70% energy savings is quite an accomplishment, and one that exemplifies the benefit of doing energy saving projects in your organization. The larger the facility and electricity bill, the greater the opportunity to find savings and the greater the payback. This particular company is already profitable and drives awareness and energy saving initiatives as a social responsibility. This particular project was certainly a success.

The company operates a factory with approximately 100 employees between the office, warehouse, and production line. The production line requires the use of four large 3-phase pumps to move liquid throughout the building and production process. As part of the energy saving project, the team installed the Eyedro Business electricity monitor to measure the baseline electricity consumption and cost. Capturing proof of the before and after results was a requirement of the project for obvious reasons.

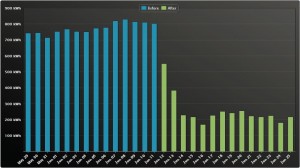

Before the project, the pumps ran continuously at a constant speed consuming a combined 800kWh per day, or $80/day if we assume $0.10/kWh. That’s approximately $2,400/month and $28,800/year. The project task was to install variable speed controllers to better match pump speed with demand. As can be seen below, the installation of the new controllers occurred on June 12th and was optimized by June 14th.

The project reduced the daily electricity consumption by the four pumps from 800kWh to 200kWh, achieving a 70% energy savings and a cost savings of approximately $20,000 per year. Hidden benefits include less heat generated (which would have required air conditioning costs to offset the heat), and less wear on the motors. The team celebrated their success but didn’t stop there. Next stop is to upgrade the warehouse lighting, a project that is certain to achieve additional energy savings.